BOREN

Dosimetry Studies

In addition to the analysis services provided for identifying irradiated foods with TL and ESR Techniques, national and international comparisons, irradiation dose estimation of irradiated foods, and method development studies are carried out on the identification of irradiated foods with the OSL technique.

In addition to the analysis services provided for identifying the dates of archaeological findings and geological samples with TL/OSL and ESR techniques, related studies are being carried out to increase laboratory capabilities by closely monitoring the literature in order to provide more relevant services.

The studies with TL/OSL and ESR techniques are carried out to investigate dosimetric materials that may be found on and/or around people in places where standard dosimeters are not available.

The efforts to develop TL, OSL and ESR dosimeters which are sensitive to different radiation types that can measure in low, medium and high dose ranges.

Fast Neutron, Proton Core Interactions Studies with Low Energy Accelerators

With the low-energy ion accelerators (150 kV-Sames J15, 400 kV Sames KS) and the locally-developed Van De Graaff type high voltage DC generator, basic nuclear physics core reaction studies are conducted to help future researchers, nuclear engineers, and reactor designers. Nuclear data are collected regarding the nuclei, particles, and different types of radiation formed as a result of the reaction. The data is made available to various researchers and material developers. Several projects are being carried out in these areas. (Obtaining Alpha Spectrum of 11B (p,α) 2α Reaction,7Li(p, α)4He reaction, etc.). On the other hand, the accelerators can also be used as neutron generators. With the fast neutrons (14.1 MeV) produced in this way, studies can be carried out on neutron nucleus reactions.

Fusion Research & Development Studies

In our institute, research activities are carried out according to the strategies identified in the fields of fusion and plasma. The purpose is to contribute to these issues by closely monitoring the developments in the world and by playing a leading role especially in the studies carried out in the country. Within the scope of plasma and fusion studies, small fusion reactors are designed and manufactured with local sources by taking into account the devices available in the world. The country's first experimental studies on small fusion reactors have been started by our Institute in 2006 and the studies are still being carried out in the Fusion Laboratory.

Within the scope of the fusion studies completed by the Institute,

Plasma focus device (ODAK-3K) and

(IEC – Inertial Electrostatic Confinement) fusion reactor (SANAEM-IEC)

have been designed and manufactured with domestic resources, in addition to neutron production research.

Currently, fusion and neutron researchs have been performed within the scope of the project entitled by "Production of Magnetic Confinement Cylindrical Fusion Reactor and Neutron Research".

These small fusion devices as the first nuclear fusion reactors have been built in Turkey in institute’s laboratories.

Food Research

Food science has a dynamic structure and its purpose to offer economical, high-quality and reliable products. In the meantime/Accordingly, food preservation methods have been studied and various food preservation methods have been developed by scientists all over the world. Simply, food preservation aims to destroy microorganisms in foods, prevent food-borne diseases, and extend the shelf life of foods by killing microorganisms that can spoil foods. . As a result of these studies, one of the applications developed for food preservation is food irradiation. Food irradiation is a technology developed to preserve the quality of foods, provide hygiene, and prolong the storage period. This technology is a physical application like pasteurization, canning, and freezing methods.

Food irradiation is a food preservation process that has been studied and researched for nearly 100 years, and food irradiation is now widely applied commercially and is regulated around the world. Food irradiation has been one of the most studied technologies of the 20th century to improve the microbiological quality and safety of foods. Studies on irradiated foods have shown that irradiation - provided that it is performed according to the criteria specified by the applicable regulations - does not cause any adverse effects on foods.

Irradiation is an effective and safe food preservation technology that extends the shelf life of foods by reducing the number of microorganisms causing spoilage in foods and ensures food safety by destroying foodborne disease-causing microorganisms. Without raw materials, there is no food. Today's world is facing raw material problems due to challenges such as climate change, water shortages, and environmental pollution. That's why post-harvest irradiation reduces post-harvest losses in the raw materials, by preventing insect infestation, hindering sprouting and delaying maturation. The presence of pests or excess pesticide residues in many fresh fruits and vegetables causes difficulties in the international trade. Many developed countries effectively use irradiation as a quarantine method for fresh fruits and vegetables, facilitating the international trade of these products. Moreover, most of the countries have restricted or banned the chemicals used to prevent insect infestation in grains, legumes or other dried foods due to their negative effects on human health and the ozone layer. Irradiation is also used as an effective treatment method for increasing the international trade value of these products. The damage caused to crops by insects alone in the world is more than 70 billion dollars annually.

To cite one or two examples around the globe, irradiation is used for different technological purposes in 14 different food groups in the United States. These food groups are: fresh fruit and vegetables, spices, seasonings and aromatic herbs, poultry meat, packaged meat and meat containing products prepared for space flight, refrigerated or frozen raw meat products, eggs in shell, iceberg and spinach, seeds, pork carcass, non-refrigerated or non-frozen raw meat products, and shellfish. In Canada, irradiation is applied to 6 different food groups. Potatoes, onions, wheat, flour, whole wheat flour, spices, dried aromatic herbs and seasonings, frozen and unfrozen ground beef constitute these groups. The European Union generally uses the irradiation process for spices and aromatic plants and accepts the foods that have been irradiated in approved irradiation facilities.

In our county, the food products that can be irradiated have been classified under 7 groups pursuant to Law on Veterinary Services, Plant Health, Food and Feed dated 11.06.2010, number 5996, as well as the provisions of Food Irradiation Legislation published in the official gazette on October 3, 2019, issue number 30907. These groups are: Onions, roots and tubers, fresh or frozen fruit and vegetables, cereals, ground cereal products, nuts, oilseeds, legumes and dried fruit, raw fish, shellfish and their products (fresh or frozen), frozen frog legs, poultry meat, red meat and their products (raw or frozen), dried vegetables, spices, dried aromatic herbs, herbs, seasonings, herbal teas and dried animal foods. Our export products include irradiated spices, aromatic herbs, and poultry.

There are two irradiation facilities in our country, one of which is belong to government and located in Turkish Energy, Nuclear and Mineral Research Agency’s Nuclear Energy Research Institute campus in Ankara, and the other is privately owned. The private facility is certified by the European Union and the exported food before exporting to the European Union have been irradiated in this facility.

Thus, research has been done to ensure that food irradiation technology is implemented in the food industry. Furthermore, it is essential to raise food irradiation awareness among manufacturers, exporters, universities, research institutes, responsible legislative organizations of governmental regulatory bodies , and the public by identifying irradiated foods using internationally-approved methods. Information is shared with researchers, students, and private and public sector representatives who interested in the subject through the Food Irradiation Course, DNA Comet Course, and internships as organized for educational purposes.

Accelerator Technologies Research & Development StudiesAccelerator Technologies Research & Development Studies

In our institute, research activities are carried out according to the strategies identified in the field of accelerators. The purpose is to contribute to these issues by closely monitoring the developments in the world and by playing a leading role especially with these studies to the country. Within the scope of accelerator researches, accelerator component studies have been conducted with the objective of designing beam lines and accelerators, identifying beam characteristics, developing data and personnel resources on particle accelerators and technologies, which have become one of the most important technologies of today.

Within the scope of the accelerator R&D studies of our institute, an RFQ proton accelerator with a capacity of 1.3 MeV has been designed and locally manufactured. With this accelerator, the energy objective of protons has been reached.

The institutional R&D studies in the field of accelerators continue with the project titled “Local Design and Construction of Klystron”. With this project, one of the most critical components in accelerators, a klystron (microwave amplifier), will be designed and manufactured. The manufactured klystron can be used as an alternative to the existing RF tube, which is the power amplifier unit of the RFQ accelerator available in our Accelerator Technology Laboratory.

Stable Isotope Separation Technologies

The isotope of 10B separation studies have been carried out within the Institute, using the chemical process infrastructure and stable isotope laboratories. As known, the natural isotope value of the boron element is % 19.8 10B and % 80.2 11B. The neutral capture of the enriched (> 90%) 10B isotope is 3837 barn, which is ~ 77000 times greater than that of 11B isotope. As a result of these properties, the 10B isotope is used widely in the industry, specifically it is used:

1) As a control bar in the nuclear industry,

2) With light metal alloys in the defense industry, and other nuclear military fields,

3) In 10B gamma armoring applications, and neutron detectors, in the modern industry and the areas of nuclear physics,

4) In boron neutron capture tray (BNCT) applications of nuclear medicine.

Within the scope of the study at our institute, the separation of the 10B isotope will be carried out using the simulated-moving bed (SMB) column chromatography separation technique. The SMB separation technique is widely used in both laboratory scale and pilot scale productions in the fields of pharmaceuticals, chemistry, and biotechnology. Due to high purity production, less solvent consumption, and higher efficiency per stationary phase, SMB column systems are preferred over other batch systems.

Material Research & Development Studies

Research and development studies are carried out for the production of radionuclide generators used in nuclear medicine research and medical imaging, which are suitable for both local and commercial purposes.

Nuclear Physics and Microelectronics

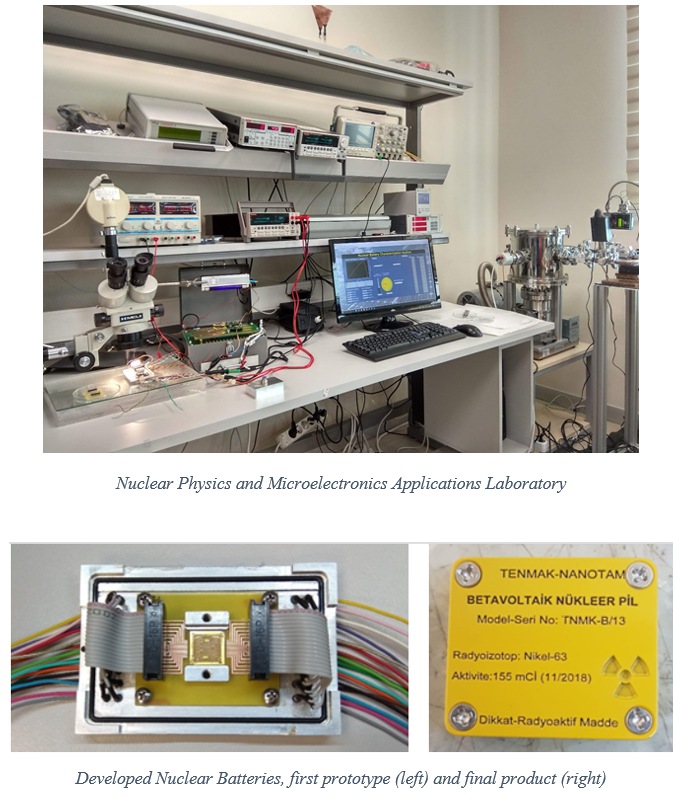

The Nuclear Physics and Microelectronics Laboratory was established within the scope of the nuclear battery project, which started in 2017 within the organization of the Turkish Atomic Energy Authority. Designed to carry out different R&D researches in the nuclear field, the laboratory housed various experimental researches in the fields of Nuclear Physics and Nuclear Electronics.

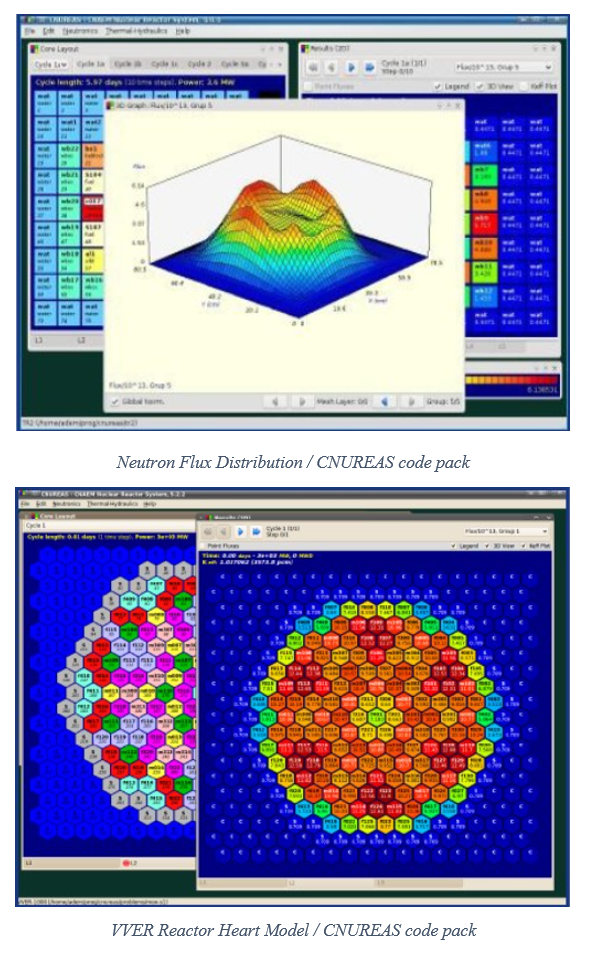

The nuclear battery project, which continues within the laboratory, has been successfully carried out in a multi-disciplinary study together with Bilkent University Nano-technology Research Center. The first stable power generating nuclear battery prototype powered by a nickel-63 radioisotope was produced at the end of 2018. Since the nickel-63 radioisotope has a service life of 200 years the prototype produced has the potential to produce energy for at least 100 years, constantly. In this context, the Nuclear Battery Project is Turkiye's first successful experimental R&D study in this field. Within the scope of the R&D project, it was aimed to increase the theoretical and experimental knowledge gained on nuclear batteries, and new project feasibility was made with several local/foreign universities, research centers, and institutions for the application of this advanced technology in today's micro-nano technology fields.

Directly charged Beta-voltaic, and radio-luminescence-based nuclear battery technologies have been studied in the Nuclear Physics and Microelectronics Laboratory. Measurements include the current-voltage (I-V) and capacitance-voltage (C-V) characteristic values of various semiconductor materials. It is possible to measure the electrostatic load, electric field and potential values accumulated on the surface of the materials with no contact under vacuum technology. Moreover, the laboratory has the necessary infrastructure for the measurement, design, and development of prototypes of gaseous and semiconductor-based radiation detector systems.

Nuclear Reactor Safety and Design Studies

In order that to adopt nuclear technology for our country, the various studies have been carried out on the design and technology of power reactors, nuclear safety analyses, and fuel cycles. By generating the qualified information to provide technical support for the licensing processes of the nuclear power plants to be built in the country we have conducted analyses on neutrons and thermal-hydraulics.

The main activities focus on the following subject matters:

Static and dynamic neutron calculations of power reactors, as well as fuel management techniques, thermo-hydraulics, and safety works.

Preparation of nuclear data libraries for reactor design, and ensuring data library applicability in terms of the calculation software requirements.

Providing support to TR-2 Research Reactor safety analysis calculations and conducting optimization works to enhance operation efficiency.

Designing and testing the project-stage reactors, developing and exchanging the necessary technologies, engaging in cooperation projects with national or international resources.

Making necessary preparations to achieve the qualification required to provide technical support to licensing processes of nuclear power plants.

Developing computer simulations and software on the power plant research, analyzing and compiling the relevant programs.

Creating and developing high-performance hardware computing infrastructure for safety analysis and design purposes of power reactor research.

Nuclear Fuel and Reactor Material Research

In our institute, studies have been carried out to investigate conventional and advanced nuclear fuel cycle processes according to the needs of our country, which has shifted focus on nuclear power technology. Typically, the studies of nuclear fuel raw material production, physical production of fuel pellets, and characterization processes of the produced fuel have been conducted . Primary research subjects are as follows:

Production and characterization of uranium dioxide (UO2), thorium dioxide (ThO2) and uranium–thorium dioxide ((U,Th)O2) nuclear fuels using conventional and advanced nuclear fuel cycle technologies

Ceramic-metal (Cer-met) nuclear fuel production and characterization

Thermal stability tests of nuclear fuels UO2 and ThO2

Production and characterization of combustible-absorbent nuclear fuels using conventional and advanced nuclear fuel cycle technologies

Inert matrix nuclear fuel studies

Nuclear fuel production studies by sol-gel method

Uranium-thorium liquid waste treatment studies

Techniques used in NYMB for nuclear fuel raw material production and nuclear fuel cycle are ammonium diuranate (ADU) and ammonium uranyl carbonate (AUC) conventional processes and sol-gel methods.

The raw nuclear fuel pellets are obtained by shaping the produced nuclear fuel raw material in desired compositions and geometries through pressing. Crude pellets are subjected to a sintering process (heat treatment) under suitable thermodynamic conditions and fuel production has been carried out for using in nuclear reactors. Quality control and characterization studies have to be carried out in all process stages, and the properties of the intermediate and final products obtained are determined whether they comply with the standards, and process changes are made when necessary.

ICP-MS (Inductively Coupled Plasma-Mass Spectrometer) analysis system is used in quality control and characterization studies, low concentration analyzes of radioactive materials such as Uranium and Thorium, impurity analyzes, and isotopic ratio analysis. Uranium analysis is performed by using the potentiometric titration method in samples with high uranium concentrations. In nuclear fuels, C, S, N, O, and H element analyses, which are important parameters affecting fuel behavior, have been also carried out with devices developed for these analyzes.

Regarding with the material characterization research, XRD (X-Ray Diffraction) has been used for the crystal structures. For the material structure, SEM (Scanning Electron Microscope) and TGA-TMA (Thermogravimetric - Thermo-mechanical Analyses) are used for the material structure and LFA (Laser Flash Analysis) is used to measure conductivity. For identifying density, a helium pyknometer is used, and for identifying porosity, a mercury porosimeter is used. BET-based surface area measurement devices are used for identifying surface area.

At our institute, analysis and evaluation services have been provided upon request within the framework of our existing laboratory facilities.

Radiation Detector Technologies and Applications

Detection and measurement of ionizing radiation are an important aspect of nuclear technology. Therefore, the our institute has maintained on interdisciplinary research and development activities regarding the production, design, and product development stages of radiation detectors by leveraging the infrastructure of Materials Research Laboratory, Radiation Detection Systems Laboratory, and Nuclear Electronics Laboratory.

The studies conducted in this context are listed below.

Scintillation Detectors

Gas Based Detectors

Other Studies

Scintillation Detectors

Scintillators are transparent materials that emit light when stimulated by radiation energy. These materials are used in the detection of ionizing radiation in nuclear technology. Scintillators are categorized into two groups, namely, inorganic and organic scintillators. The advantages and disadvantages of these materials are detailed in the table below.

|

ORGANIC SCINTILLATORS |

INORGANIC SCINTILLATORS |

||

|

ADVANTAGES |

DISADVANTAGES |

ADVANTAGES |

DISADVANTAGES |

|

Fast response time |

Low light efficiency |

Hight light efficiency and linearity |

Rather slower response time |

|

Possibility of producing in desired sizes, easily can be made processed and shaped |

Susceptible to high radiation damage |

High density and high effective atomic number (Zeff) |

Difficult and complex crystal growing processes for single crystals |

|

Low cost |

Low density, lower effective atomic number (Zeff) |

High energy resolution |

High cost |

Scintillation detectors, on the other hand, consist of the scintillator material and the photomultiplier located just behind this material, which converts the light emitted by the scintillator material into an electrical signal. Today, scintillation detectors are used in medical imaging devices such as computed tomography (CT) and positron emission tomography (PET). In addition, these detectors can be found in security scanning (in areas requiring national security such as airports and border security gates), mining (identifying new resources), astrophysics, particle physics, and high energy physics, as well as accelerator experiments.

Inorganic Scintillation Detectors:

In addition to their high density and effective atomic number values, inorganic scintillator materials have attracted great attention in recent years due to their superior optical properties (high luminous efficiency, high energy resolution, short down time, etc.).

The institutional studies on inorganic scintillators have shifted the focus to new generation polycrystalline ceramic scintillators, which allow the detection and identification of ionizing radiation, and whose production methods are easier and cheaper than single-crystal materials. The studies have involved that synthesis and characterization of ceramic scintillator powders by wet chemical methods using the infrastructure of the Chemical Process and Material Production Laboratory; transformation of the synthesized ceramic powders into final radiation detector products with powder metallurgy processes; development of quality control processes, optical and mechanical properties of the produced materials.

Studies have been carried out on electronic circuit design (which can, under radiation, detect the shimmer of the produced transparent polycrystalline ceramic scintillator materials with silicon photomultiplier photodiodes); tests and calibration; application development within the scope of software and mobile device integration.

A-/Improving of Nuclear Meter Devices

Within the scope of this study, which has been going on since 1986, the objective is to develop and produce radiation measurement and monitoring device prototypes in various sizes and features, suitable for today's technology. While dozens of model device prototypes have been developed within the scope of the project, new radiation measurement devices are being developed with the experience and knowledge gained from this research to technologically compete in the world. Since advanced micro-controllers are used in the devices, both radiation dose rates and radiation doses can be accurately measured. Geiger Müller (GM) detectors with halogen damping and energy compensation are used in the devices.

The developed devices have been manufactured and supplied used in the various institutions, especially in the universities, hospitals, industrial organizations, and also in the units of the Turkish Armed Forces and the General Directorate of Civil Defense throughout the country.

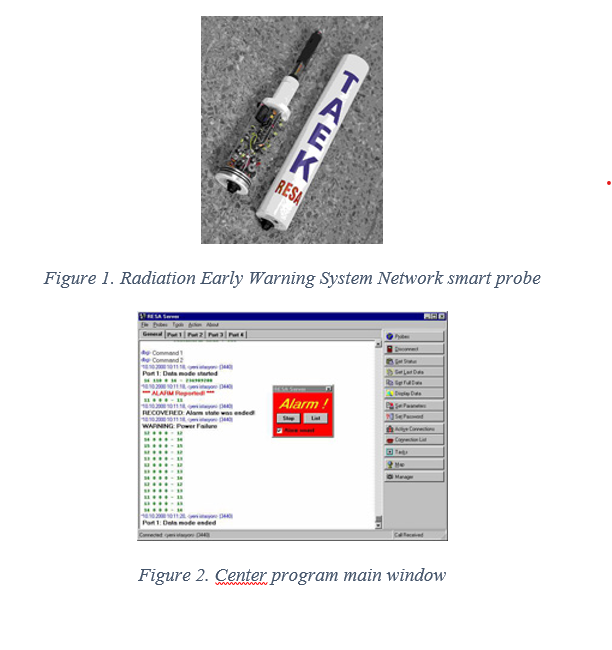

Radiation Early Warning System Network

The developed Radiation Early Warning System Network consists of a large number of “Remote Stations” where ambient radiation is continuously measured and evaluated, and a “Central Station” that provides the management of these stations and the storage and evaluation of the data received from the stations.

In each of the developed remote stations, there is a "Smart Probe" in which radiation measurement detectors and measurement circuits are placed, and a "Supply Unit" containing modem and uninterrupted power supply. The smart probe measures the radiation dose rate from the natural radiation level up to 400 R/h by means of 2 Geiger Müller (GM) detectors that sensitive to gamma and x-rays. Radiation dose rate measurement is calculated with 2 different operating modes, "fixed sensitivity mode" or "average mode", which can be chosen from the center. In fixed sensitivity mode, the measurement time is variable and is terminated when 95% measurement accuracy is reached depending on the radiation dose rate. In the average mode, however, the measurement time is fixed, the measurement accuracy is calculated by the probe depending on the radiation dose rate at the end of the fixed period and the measurement result is stored in the probe memory as a "record".

Established remote stations in different parts of our country, especially in the border regions, automatically transfer the radiation measurement data they have accumulated in their memory to the Central Station in Ankara, together with an alarm warning in case of possible radioactive contamination due to a potential increase in the radiation level or a malfunction in the system.

Radiation Early Warning System Network Central Station, as one of the two main parts of the system, consists of a computer and modem unit on which the Radiation Early Warning System Network Central program runs. The Radiation Early Warning System Network Center program manages the stations and results of measurement by minimizing human intervention. Menu interface is seen on the main page of the program in Figure 2. Created with the PASCAL programming language the software can run on any PC under the Windows operating system, and is designed to demonstrate the desired results to the user in the graphical environment (Fig. 3). For example, the stations can be seen on the maps created in the Radiation Early Warning System Network Central Station software (Fig. 4), and the station-related operations can be performed over the interface.

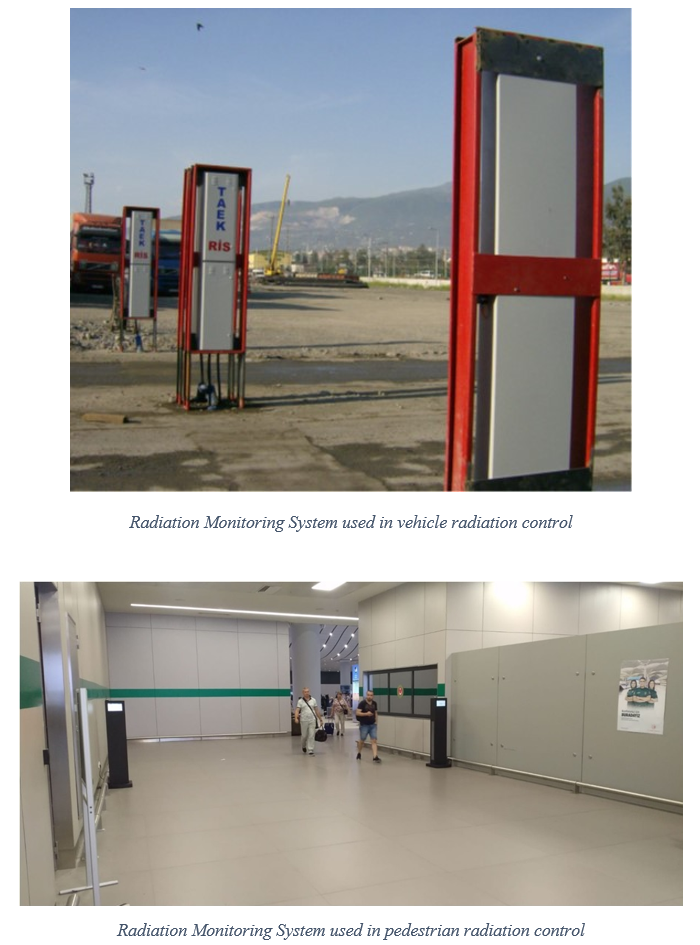

C-Radiation Monitoring System

Designed to monitor the radiation movements in our country, the Radiation Monitoring System detects uncontrolled radioactive materials and ensures timely intervention. The system has been installed at the Customs Gates (Land, Air, Sea) and has been continued to be installed as needed. NÜKEN oversees the data communication between the system and the General Directorate of Customs Enforcement throughout the country to ensure real-time radiation measurement and control. Moreover, the Radiation Monitoring System is installed for enterprises and organizations focusing on recycling activities.

Converted into electrical signals through the plastic scintillator detector and photomultiplier tube in the system, and evaluated by electronic circuits with micro-controllers, radiation measurements can be monitored via a computer or an internal monitor.

Radiation Technology Applied Research

Two types of radiation sources are used in radiation technology. The first type is the radioisotopes Co-60 and Cs-137, which emit gamma rays, and the other is electron beam accelerators, where high-energy electrons are produced. Today, X-rays have also started to be used as a common industrial source of radiation.

In irradiation facilities where such sources are used, hundreds of materials with various properties, structures and appearances are irradiated, from automobile tires to food, from telephone cables to flue gases, from plastic films in the packaging industry to hospital equipment. Mainly, the applications of irradiation technology are based on the principle of initiating chemical reactions by using radiation energy, creating biological changes, and thus improving the physical and chemical properties of various materials. Fundamentally, it is not only an easy application but also its most important advantage is that it can be applied to gases, liquids, solids, homogeneous or heterogeneous systems without requiring any catalyst. The most important advantage of radiation technology over other technologies is that it can minimize the dependency on chemicals and temperature levels. Another significant advantage is that it provides energy-saving.

NUKEN has gamma source and electron accelerator as the irradiation infrastructure and related studies have been conducted on the following subjects:

- Treating stack gas,

- Protecting cultural heritage,

- Treating industrial solid and liquid wastes

- Polymeric based membrane, hydro-gel, and burn dressings.

Moreover, the current infrastructure is capable of conducting studies on:

- Surface grafting of polymers,

- Membrane production (for fuel cell, filter, ion separation, etc.),

- Transparent teflon production,

- Burn treatment dressings and dialysis systems,

- Production of biocompatible nano-particles (drug delivery systems)

- Improving the mechanical properties of polymers,

- Production and repair of polymer matrix composite materials for aircraft, helicopter wings and bodies,

- Developing new types of mutagenic seed variations,

- Surface sterilization,

- Developing new advanced technologies, and transferring them to industrial applications,

- Developing high-tech materials such as silicon carbide and boron carbide with radiation technology,

- Aging with radiation,

- Studying the effects of radiation on materials

Radiologic Monitoring Activities

For nuclear plants we provide radiological monitoring program preparation and implementation services.

Preparation and implementation of radiological monitoring program services are provided for plants that will perform rare earth element (Thorium and Uranium) extraction, processing and storage activities.

Radionuclide Metrology Research

Following activities are carried out within the scope of radionuclide Metrology research.

- Validation and application of secondary and primary standardization methods,

- Radioisotope and dosimetric measurement and calibration services,

- Ensuring the reliability and traceability of the measurements made in our country by organizing qualification and comparison tests for the relevant laboratories,

- Preparation and production of radioactive standard source and reference materials needed in our country,

- Developing and sharing knowledge and experience on ionizing radiation metrology by cooperating with relevant institutions and organizations,

- Cooperation with national and international organizations in the field of ionizing radiation metrology,

- Strengthening the infrastructure of ionizing radiation metrology by participating in international metrology research projects.

We have participated in the international project titled MetroERM ENV57 "Metrology for European Radiological Early Warning Networks", supported by the European Metrology Research Program (EMRP) and overseen by Germany's Metrology Institute PTB. Within the scope of the "Airborne Radioactivity Monitoring Networks" work package, rapid analysis methods have been developed for alpha emitting radionuclide (241Am, 238Pu, 288Th, 238U) and 90Sr in air filters for post-nuclear accident conditions.

In the Radionuclide Metrology Laboratories, reference measurements are made and radioactive standard source and reference materials are produced with the systems and devices used in the standardization of radionuclide emitting alpha, beta and gamma radiation. Most of the systems and devices are unique in our country. In addition to national and international training and workshops, qualification tests are also organized.

National and international qualification tests organized by Radionuclide Metrology Laboratories are listed below:

TAEK-RMB-2013-01 Qualification Test on Determination of Activity Concentrations of Natural Radionuclide in Soil

TAEK-RMB-2015-01 Qualification Test on Determination of Cs-137, K-40 and Sr-90 Activities in Processed Tea

TAEK-RMB-2018-01Qualification Test on Determination of Activity Concentrations of Natural and Artificial Radionuclide in Water Samples

The sample of the qualification test held in 2015 was certified as TAEK-RM-1 Black Tea Powder and released as a radioactive standard reference material.

Agricultural Research

Agricultural research is one of the areas where nuclear techniques are used most intensively. The purpose of using nuclear techniques as agricultural research tools is to find solutions to agricultural problems that cannot be eliminated with traditional methods. In addition to leading the R&D studies in original projects, our purpose is to promote nuclear techniques in the country's agriculture, and provide the relevant organizations with the technical data obtained. By Organizing and conducting the national and international training courses, the nuclear techniques in agriculture and related information are provided to researchers and internship students.

Therefore, the following studies are being conducted:

- Plant breeding research to develop new varieties,

- Studies to examine soil-plant-nutrient-water relations,

- Studies on plant protection and pesticide residues.

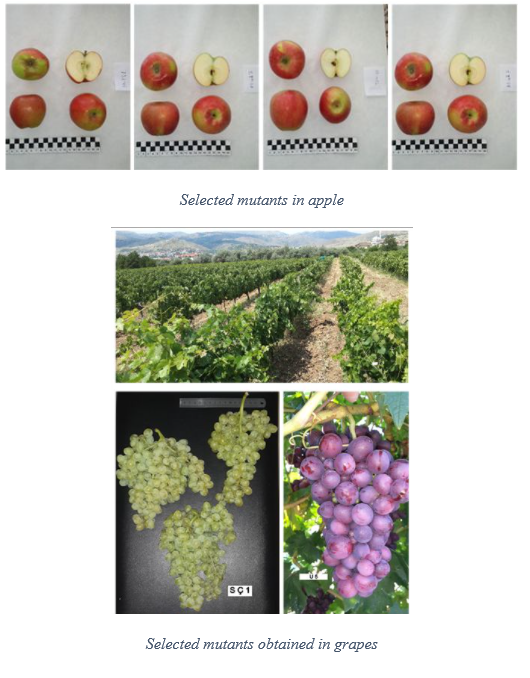

The purpose of plant breeding studies is to create genetic variations by using nuclear and advanced techniques - known as mutation breeding -, to select new, superior mutant types from these variations suitable for breeding purposes (high yield, quality, resistance to diseases and pests, etc.), and offer them to Turkish agriculture. Thus, breeding studies are carried out by engaging in cooperation for certain species such as chickpeas, wheat, barley, tomatoes, lettuce, grapes, cherries, apples, apricots, pistachios, olives, oranges, and chrysanthemums. New mutant varieties have been developed as a result of the long-term breeding studies carried out so far. The mutant varieties have been registered by the Ministry of Agriculture and Forestry's Directorate of Seed Registration and Certification Center. Registered in the Mutant Variety Database of the International Atomic Energy Agency, these mutants include soy varieties with high-efficiency, high-oil, and protein values (TAEK A-3 and TAEK C-10), tobacco varieties with resistance to blue mold disease (TAEK-TUTLUER and TAEK-PEŞKİRCİOĞLU), protein-rich chickpea varieties with fast-cooking time (TAEK-SAĞEL), high-quality cherry varieties (ALDAMLA and BURAK), and an early-comer, high-yield potato variety (NAHİTA). Right now, production permission has already been granted to our two mutant tomato variety candidates by the Ministry of Agriculture and Forestry's Directorate of Seed Registration and Certification Center. Furthermore, we continue to work on mutant candidate plant types for registration in other species as well.

The purpose of soil fertility and plant nutrition studies is to use tools like Radioisotopes (15N etc.) and Neutron probe to:

- Identify the plant efficiency of using fertilizers and water,

- Determine the fertilizers relationship with the environment,

- Determine the mineralization and immobilization rates in soils

- Accurately detect the fertilizer movements in the soil.

Thus, it is possible to increase plant production and develop appropriate methods to reduce environmental pollution caused by fertilizer and water use.

In addition to these studies, researches are also carried out on increasing yield and product quality with drip irrigation + fertigation. Biological nitrogen fixation capacities of legume plants are determined and foliar fertilization studies on fruit trees are carried out using the 15 N technique.

The objective of Plant Protection Laboratory is to seek solutions to plant protection issues by using nuclear and traditional techniques together. The studies carried out for this purpose are summarized below:

- Fundamental studies on Sterilized Insect Technique, which has become important for our country, recently.

- Identifying the disease and pest resistance of mutant lines of the field and horticultural crops developed by mutation breeding.

- Prevention of significant storage diseases and pests seen in stored products with gamma radiation applications. Determination of sterilizing and lethal doses of various warehouse pests.

- Identifying the pesticide resistance by using the radioisotope monitoring technique. Analyzing the accuracy and reliability in the pesticide residue processing steps.